CRC Evapo-Rust® Products

Best rust remover available on the market today. It is simple and easy to use, with no need for mixing

Combines the rust remover power of Evapo-Rust® with the ability to cling to vertical, rusted surfaces.

Protect from rust with our water-based rust inhibitor. Prevents rusting for up to 1 year.

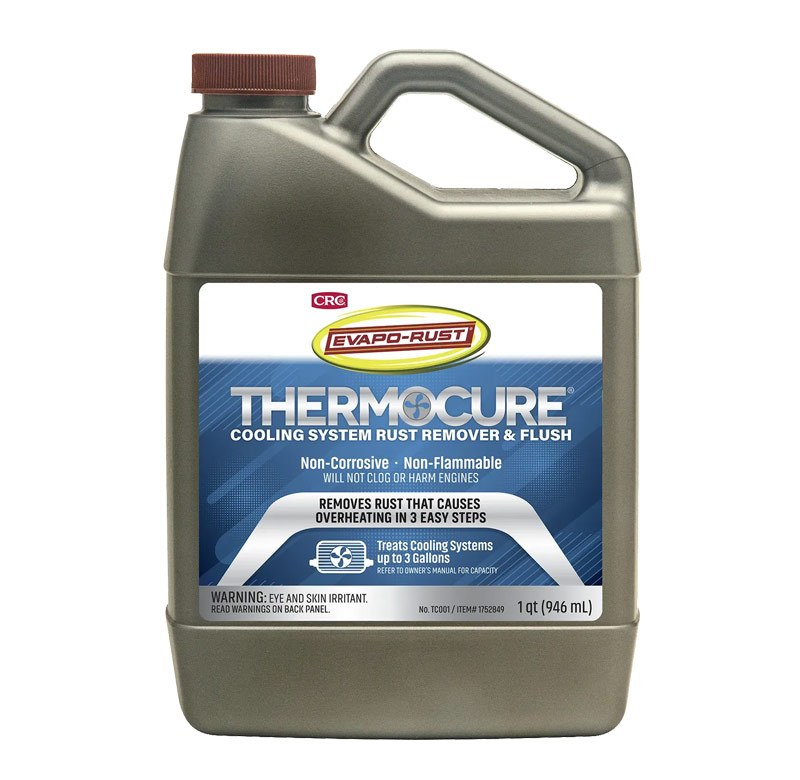

Removes rust scale and deposits from radiators, water pumps, water jackets, engine blocks, and heads.